19

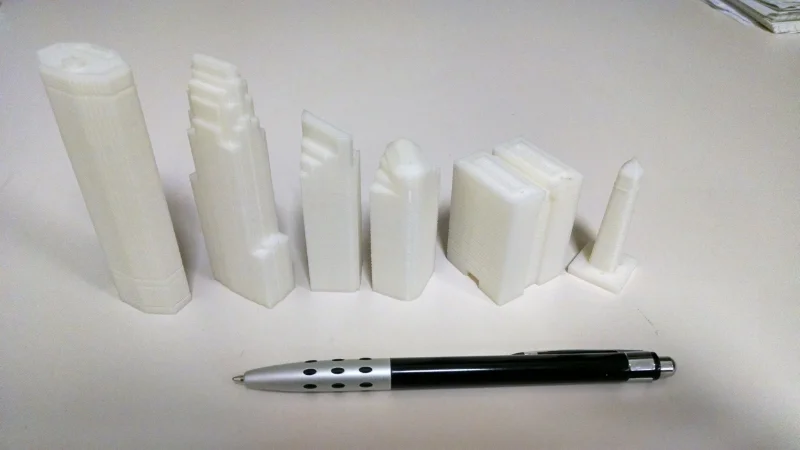

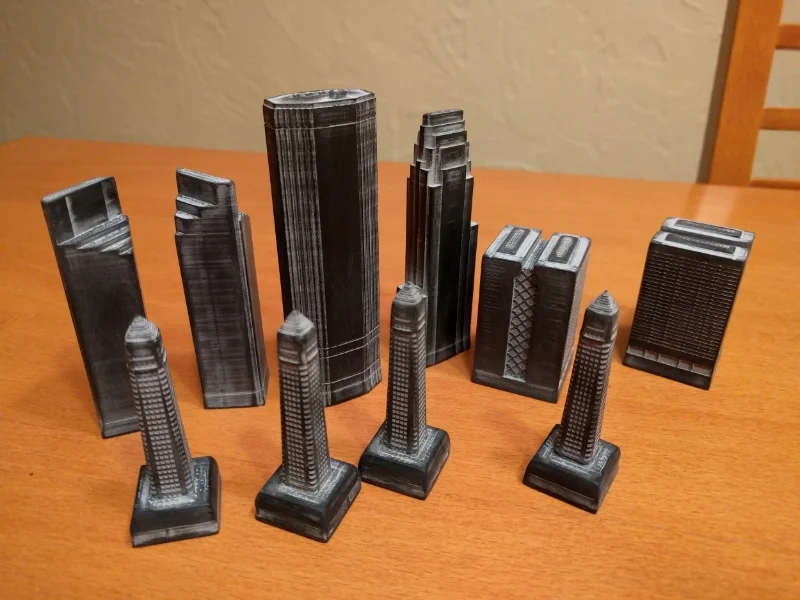

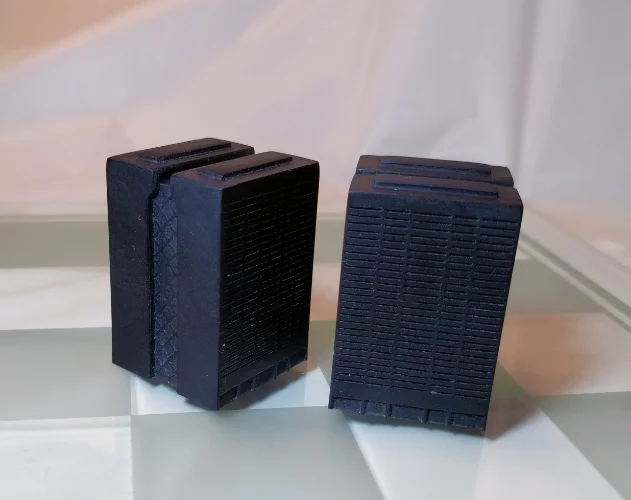

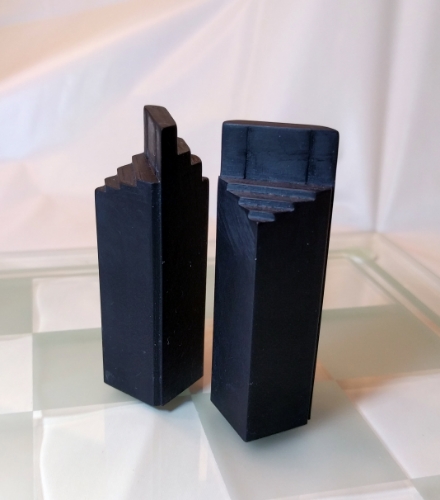

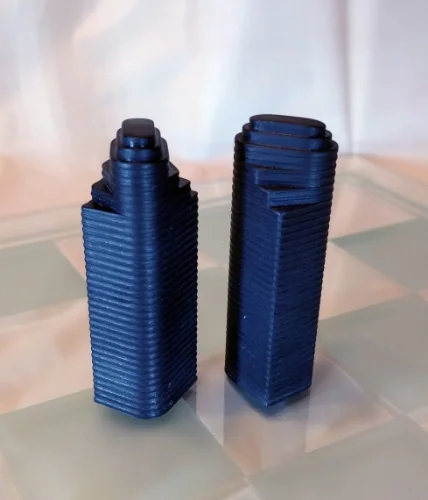

Minneapolis Skyline Chess Set

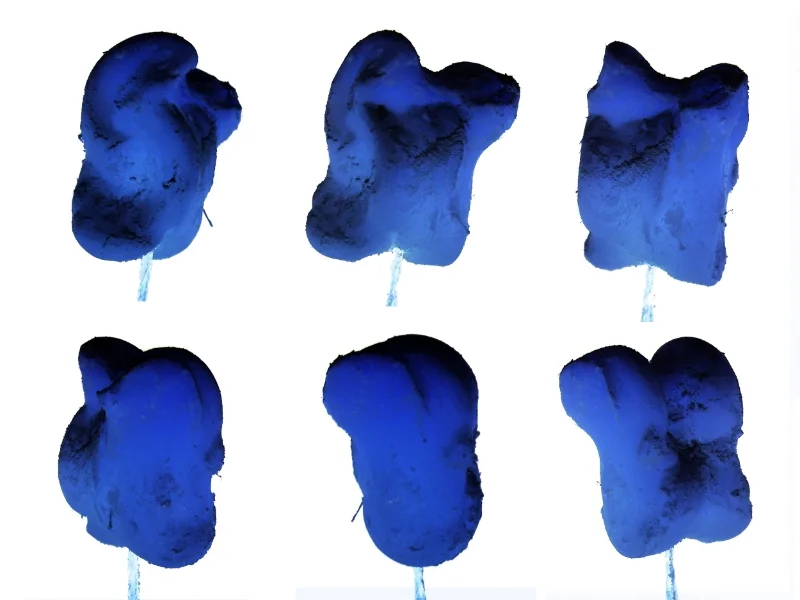

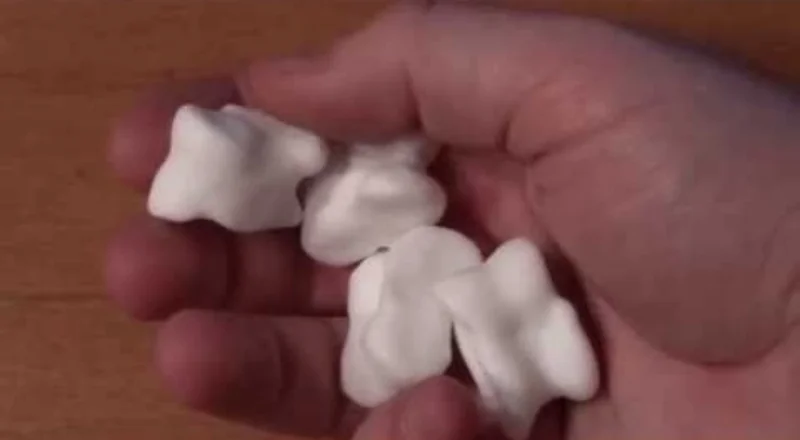

5

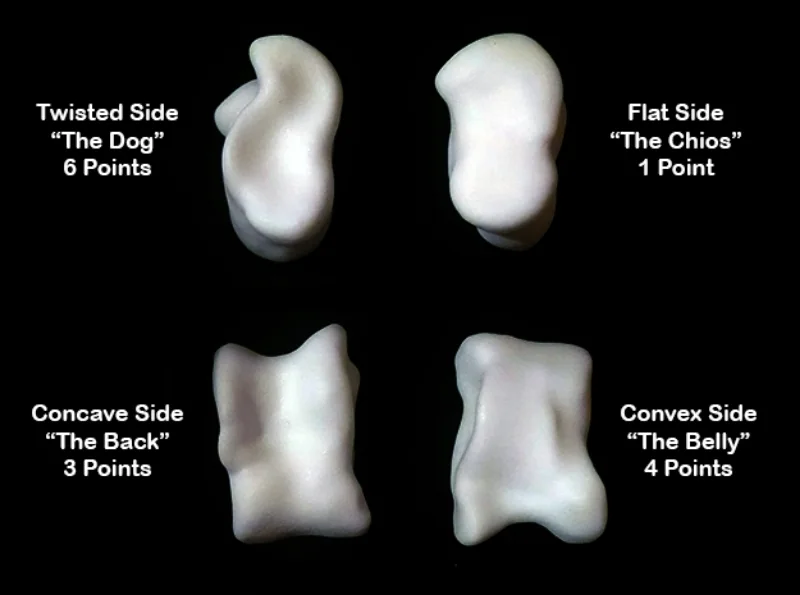

Knucklebone Dice

8

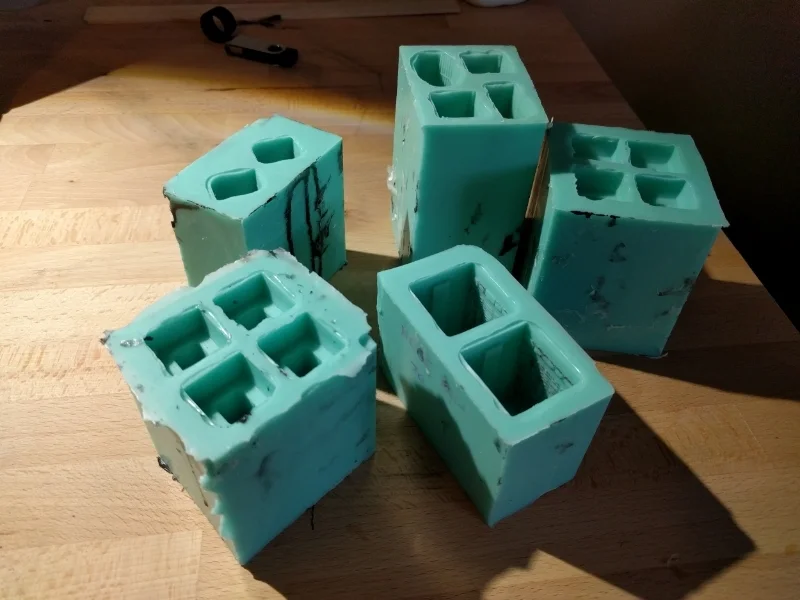

3D Printed Concrete Castle

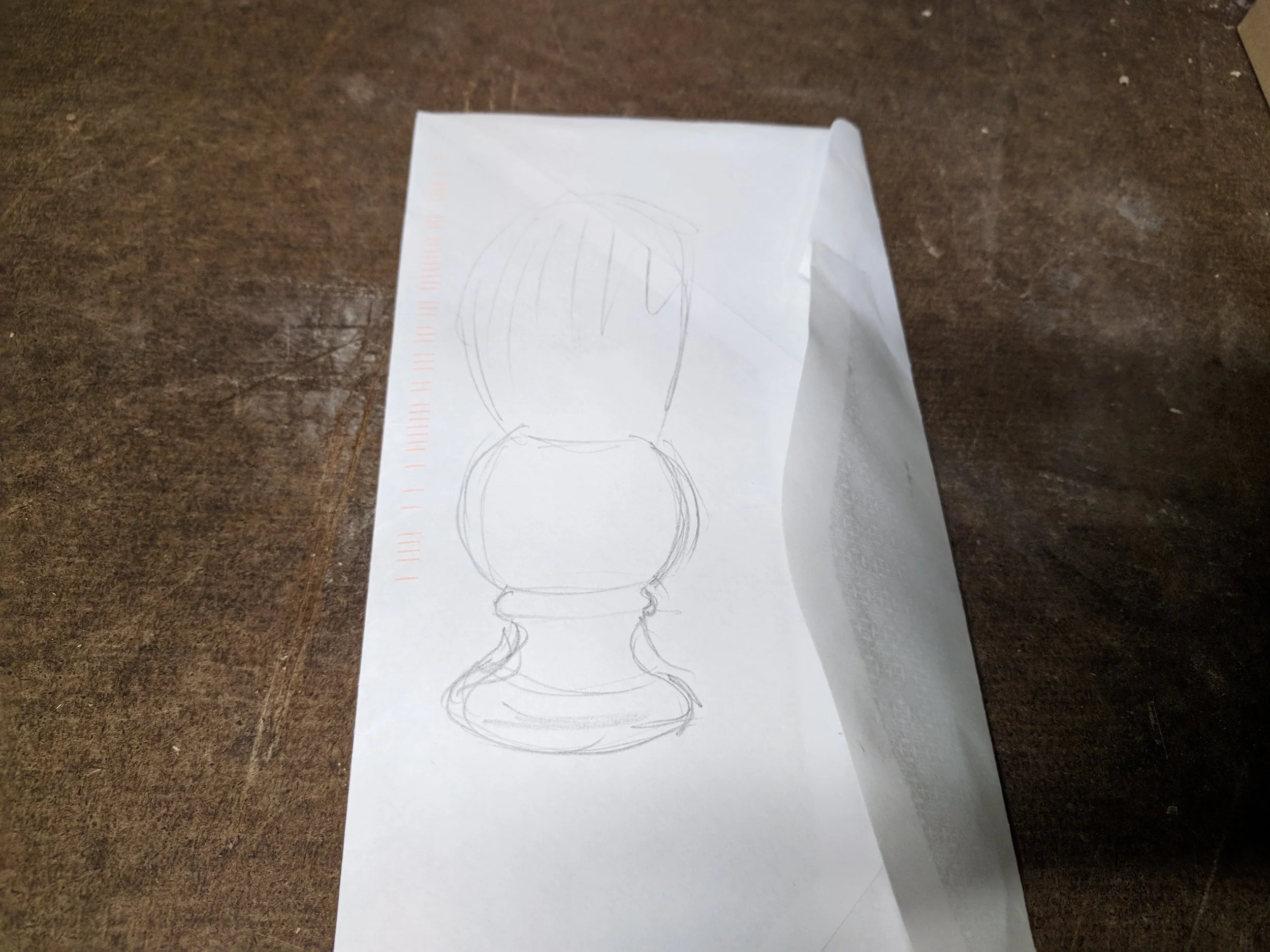

12

Shaving Brush Handle

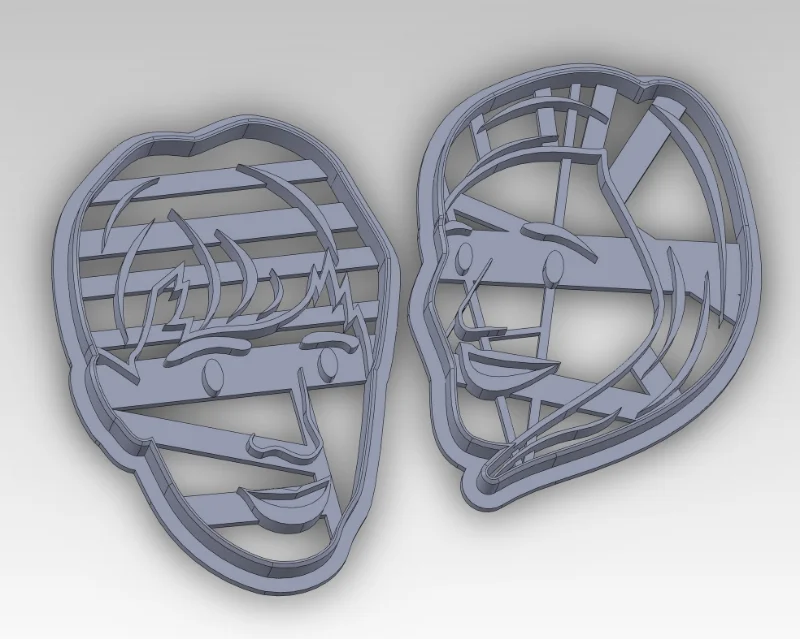

7

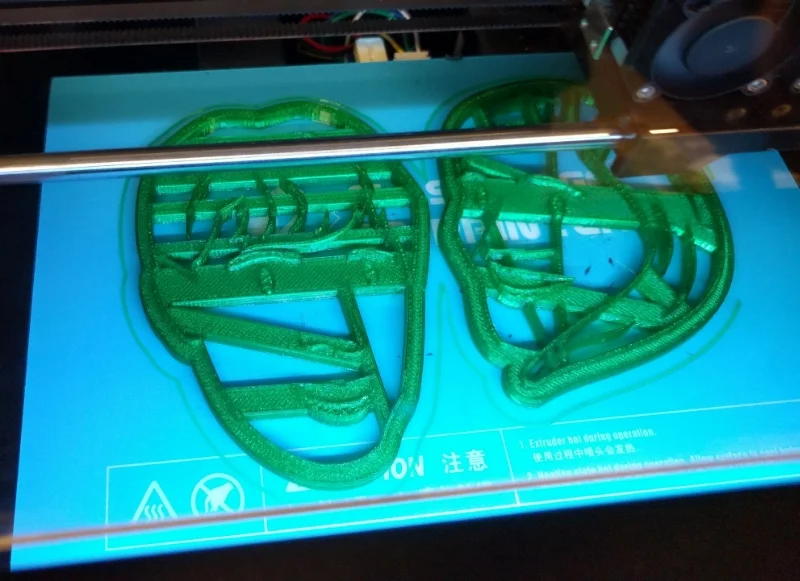

Cookie Cutters

11

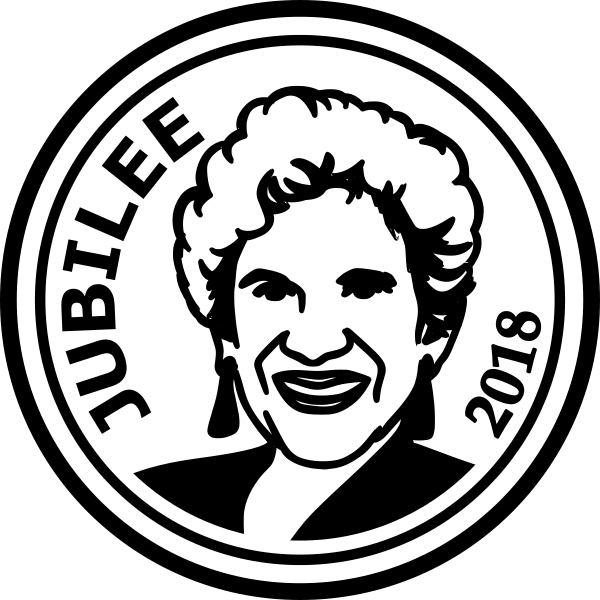

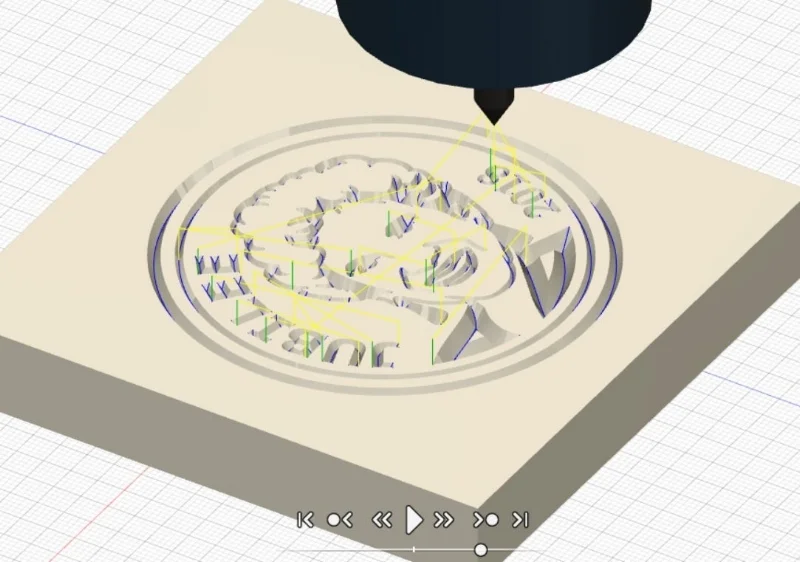

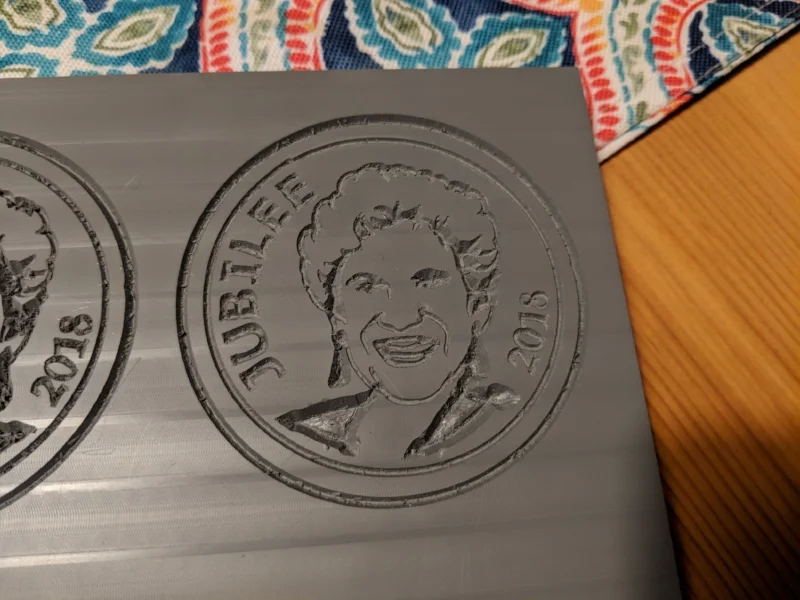

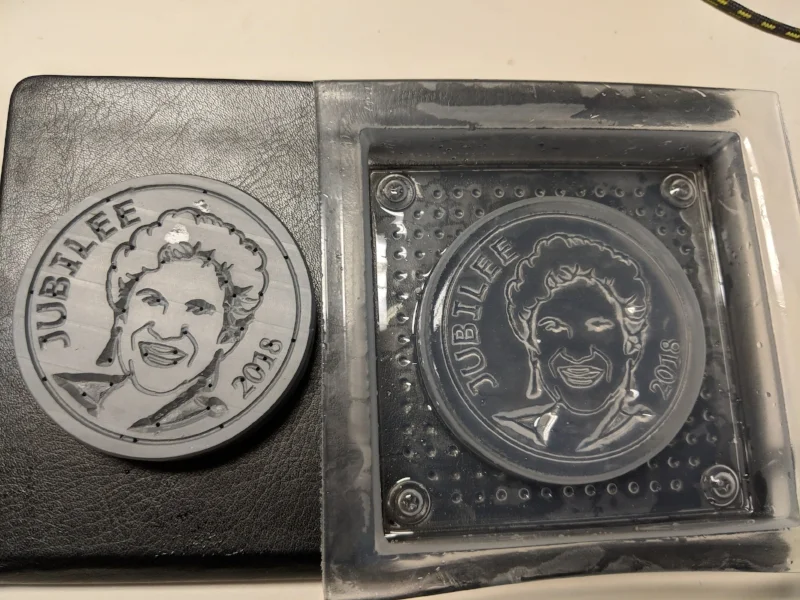

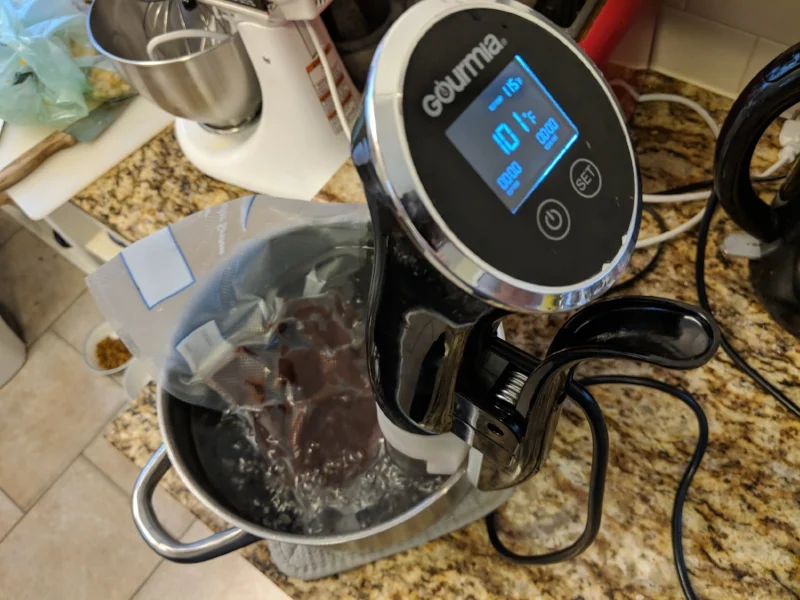

Chocolate Medal

11

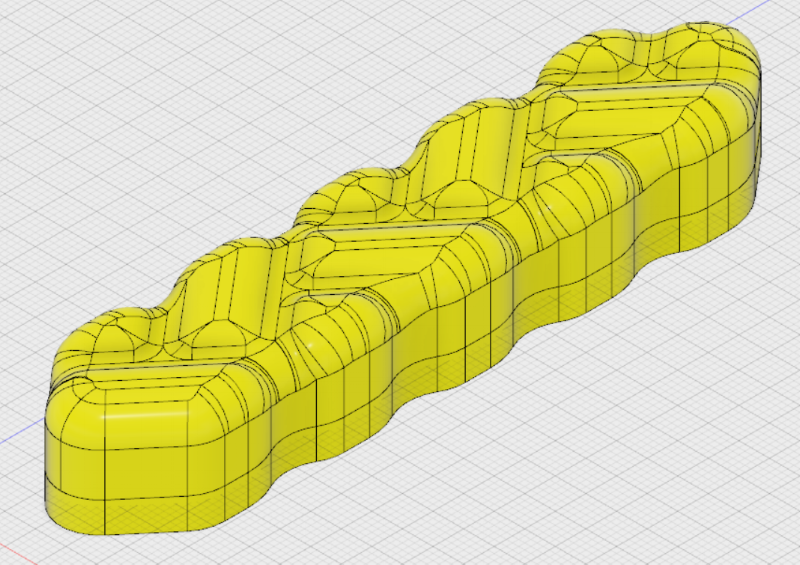

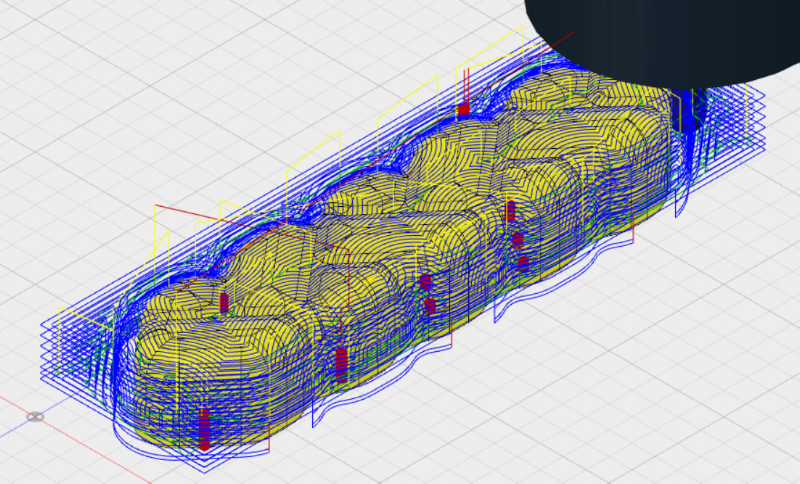

Challah Bread Board

13

Wooden Pull Toy

6

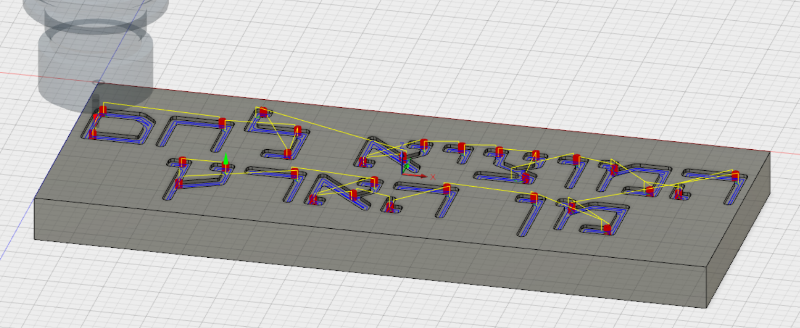

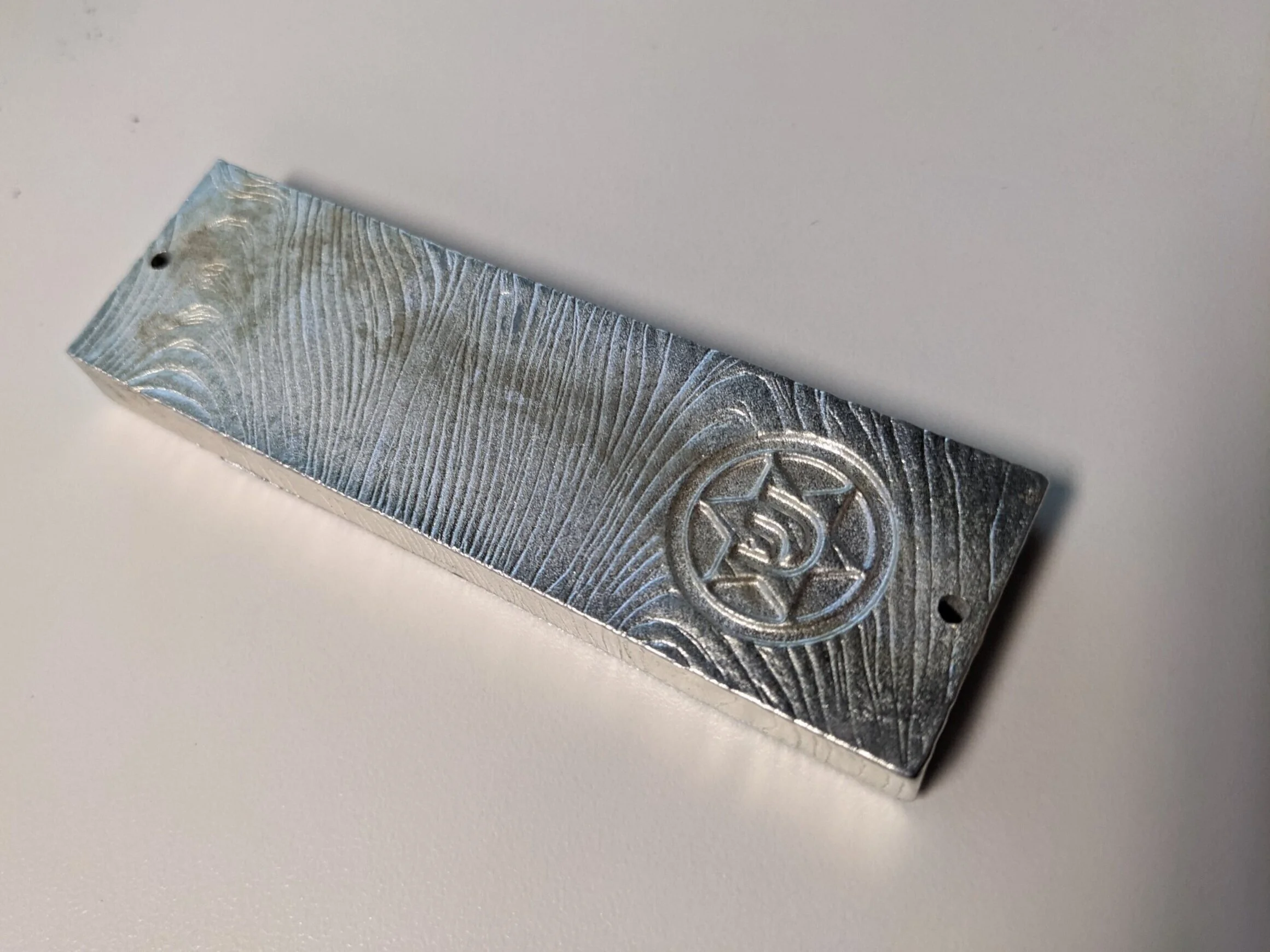

Beskar Mezuzah

13

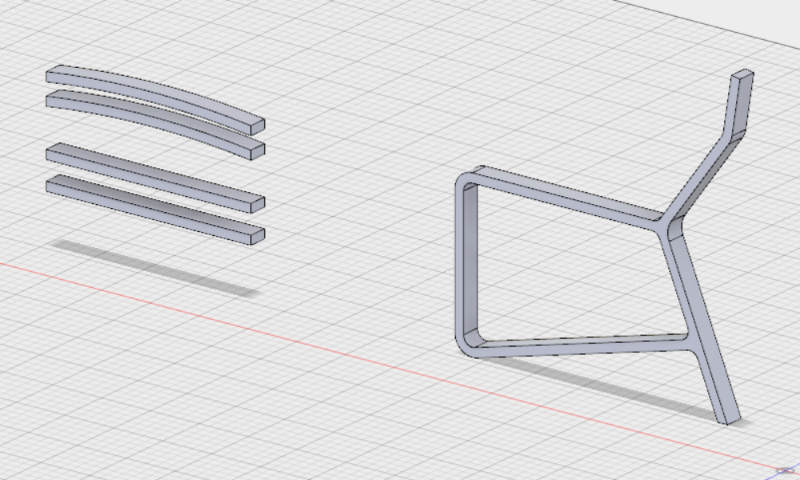

Toro Sling Chair Scale Model

5

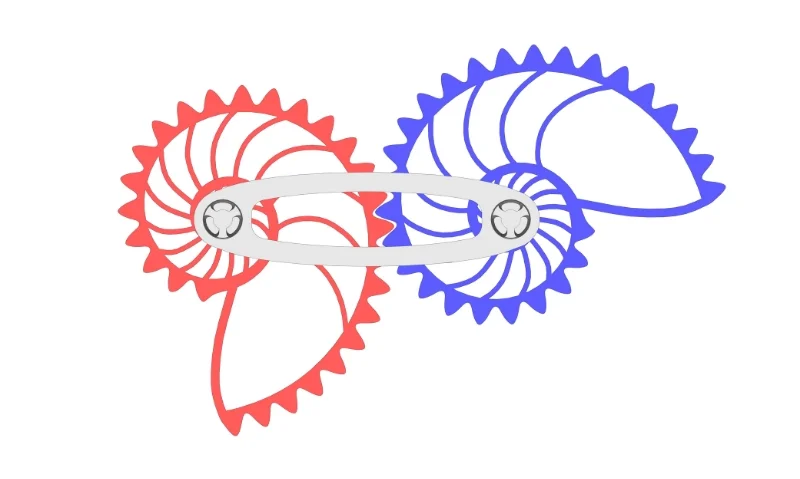

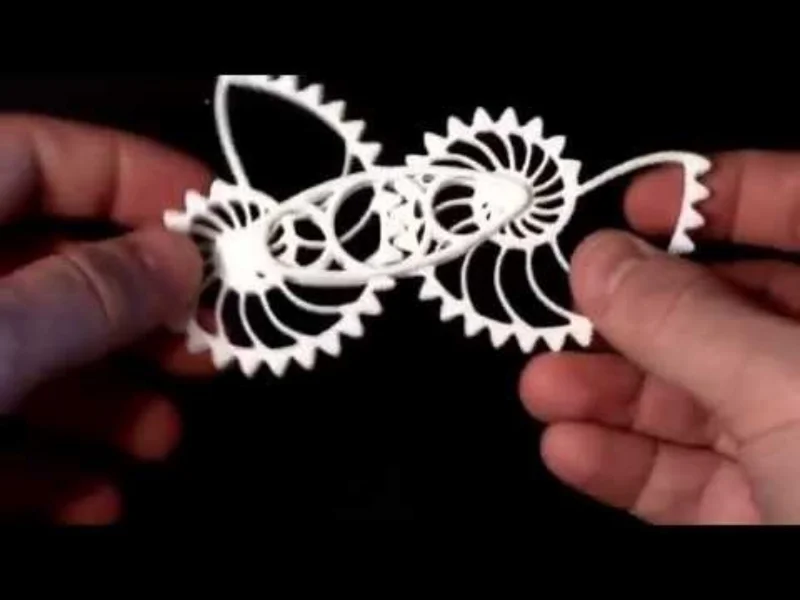

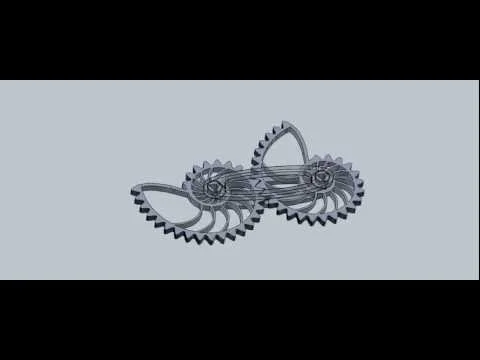

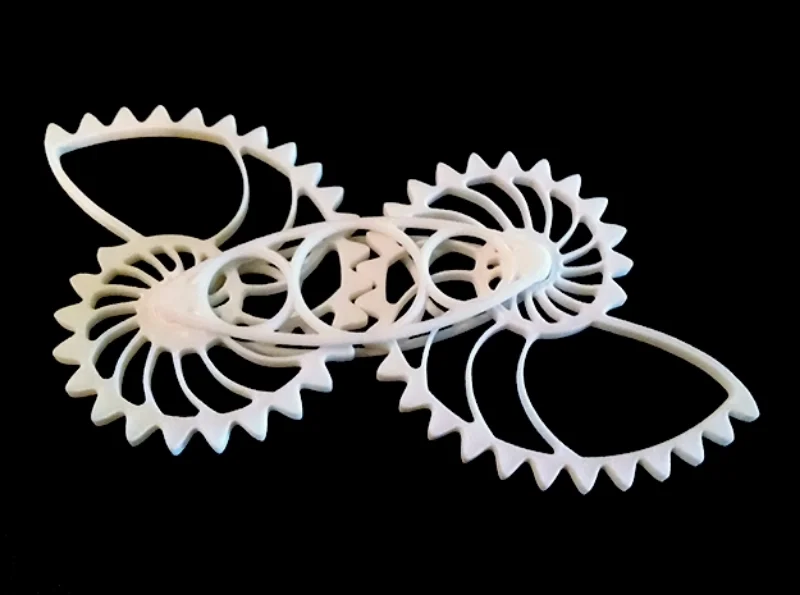

Nautilus Gears

4

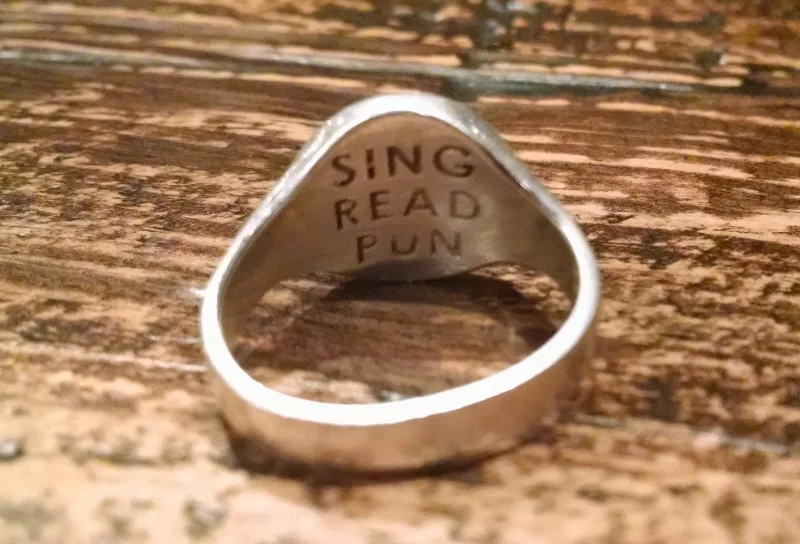

Family Crest Ring

4

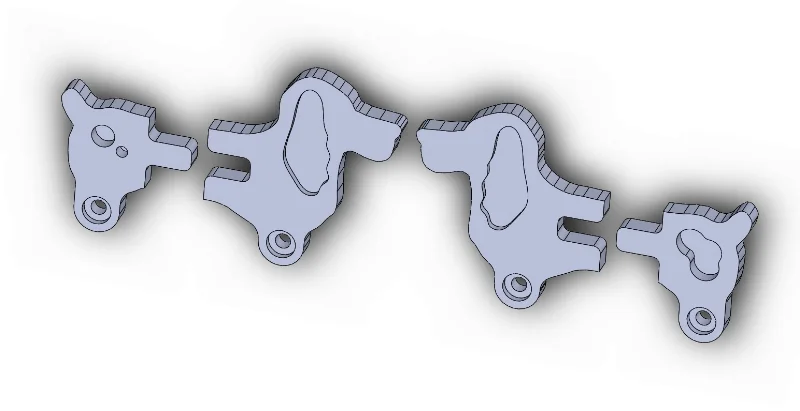

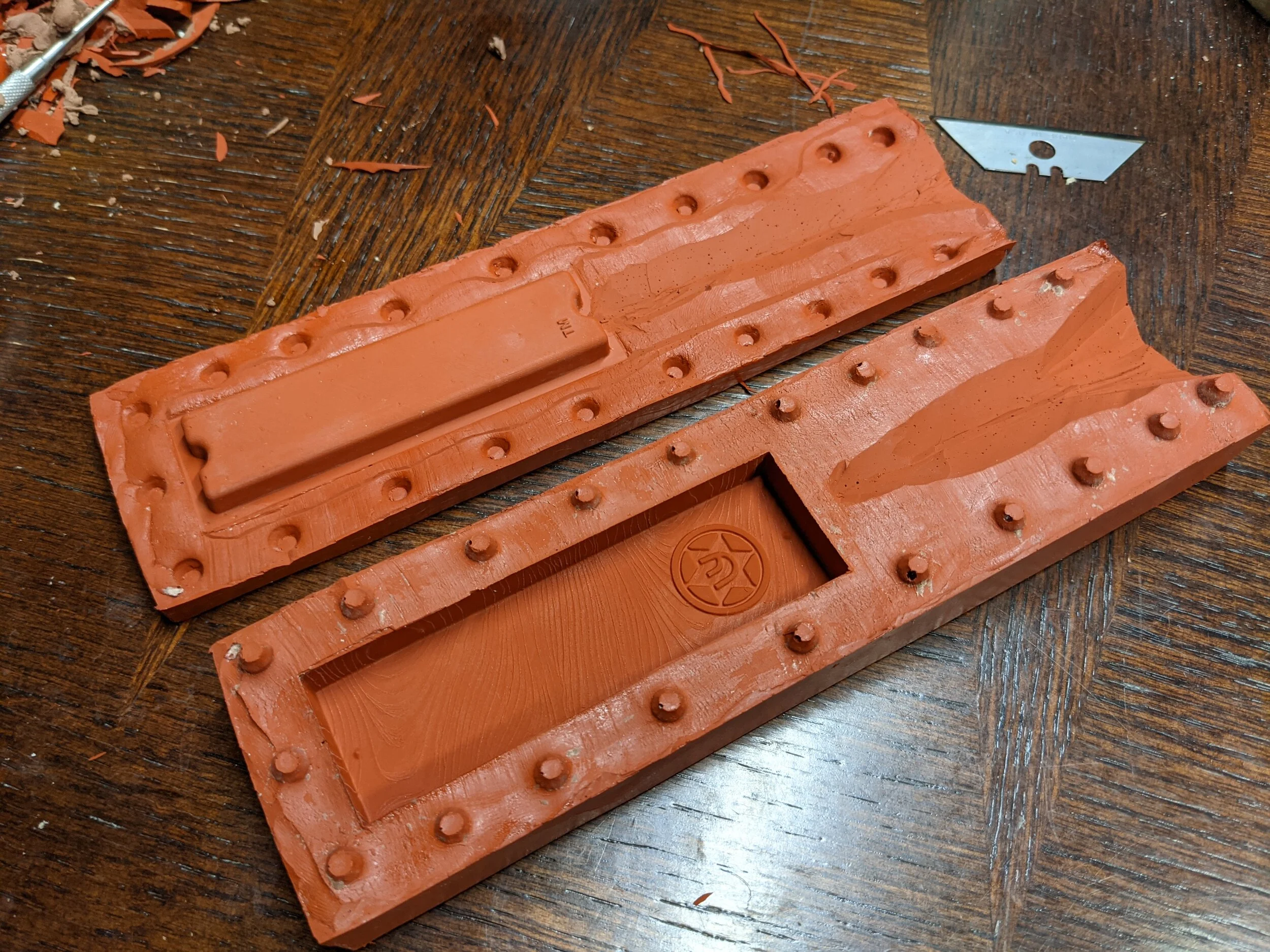

Challah Mezuzah

6

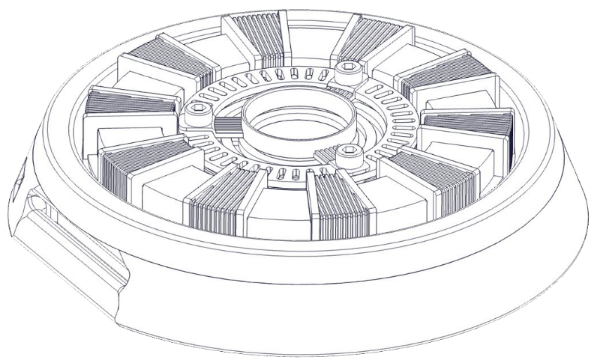

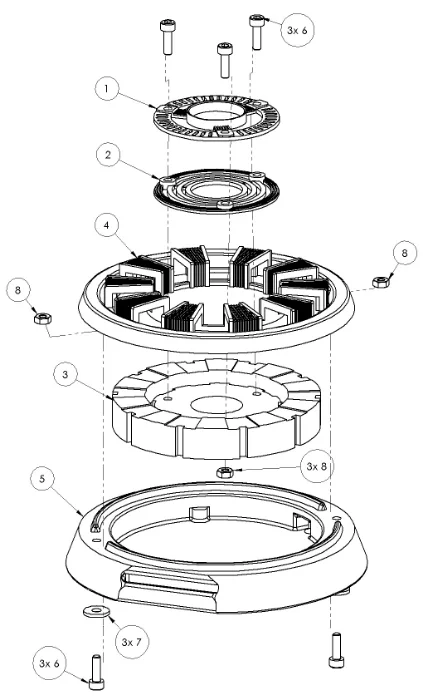

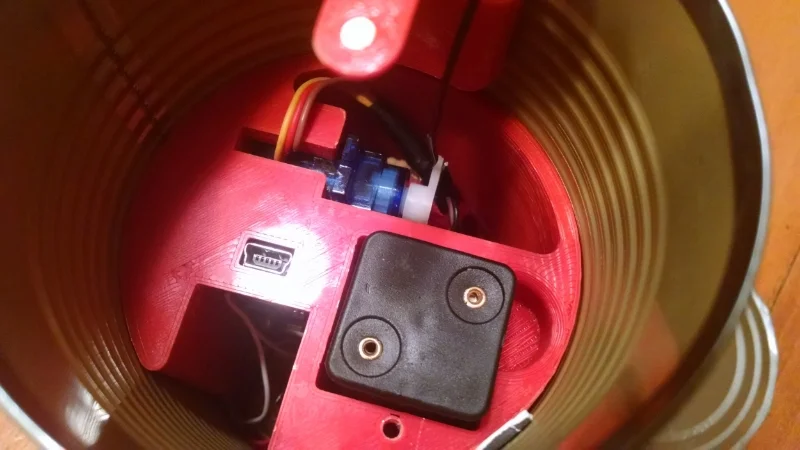

Arc Reactor

5

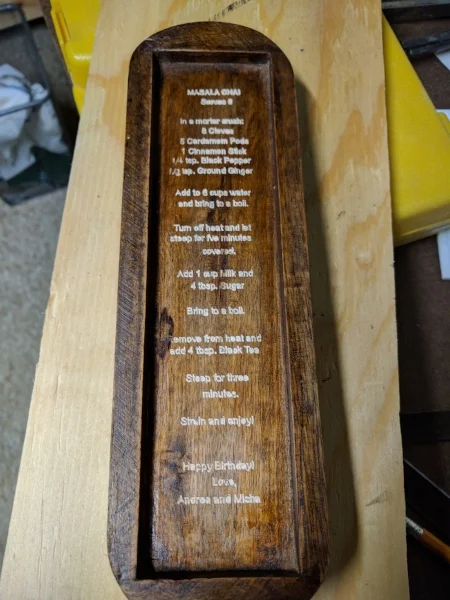

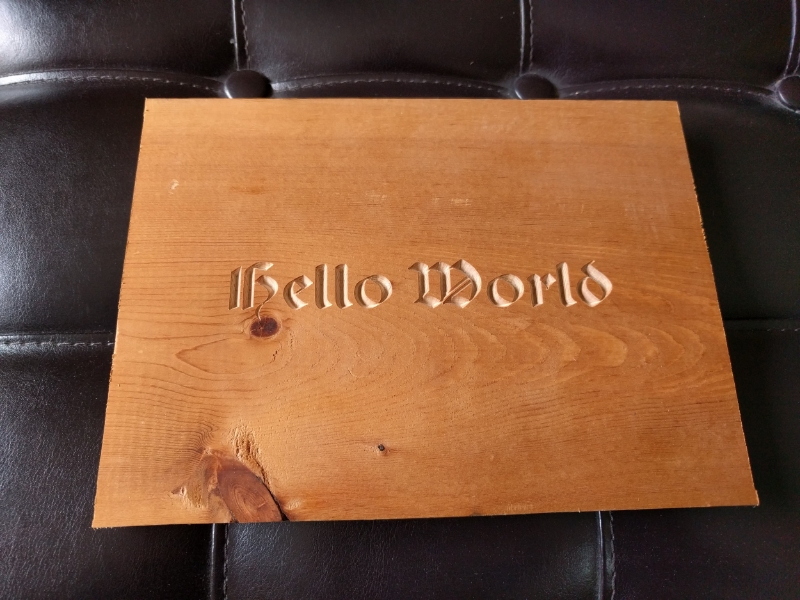

Engraved Gift Box

17

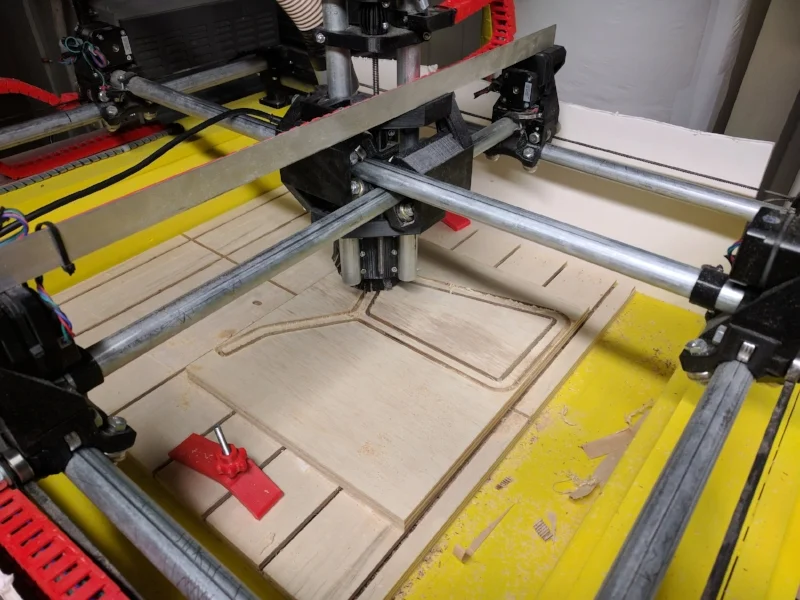

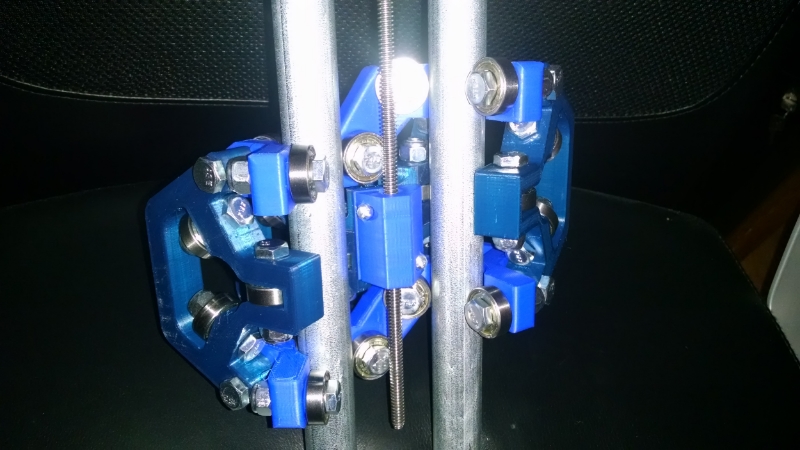

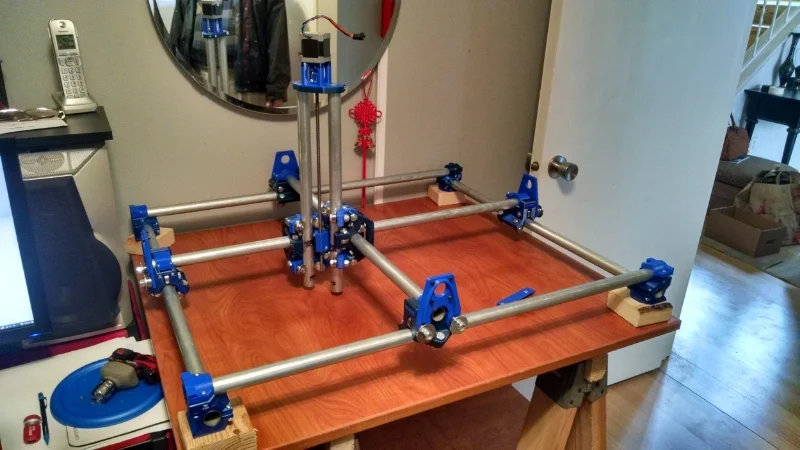

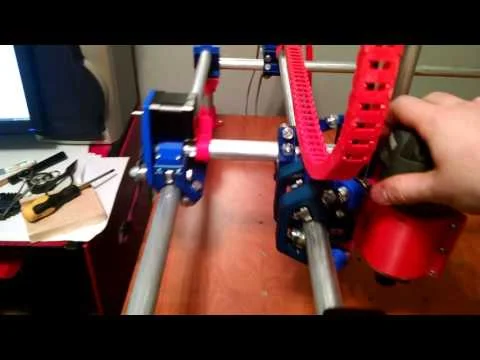

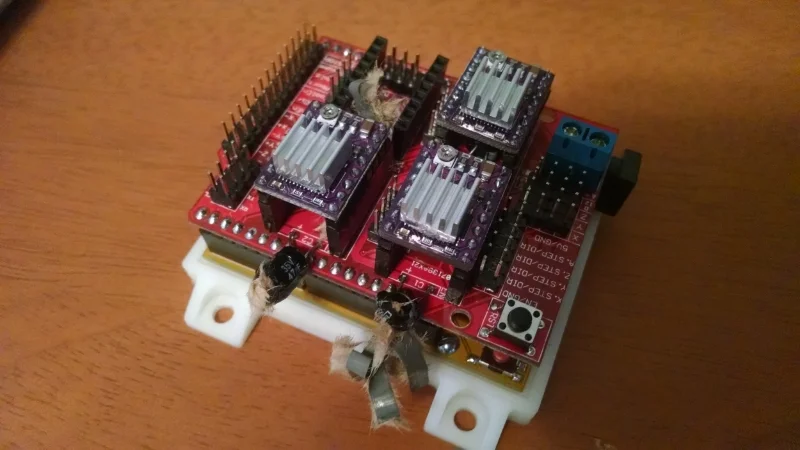

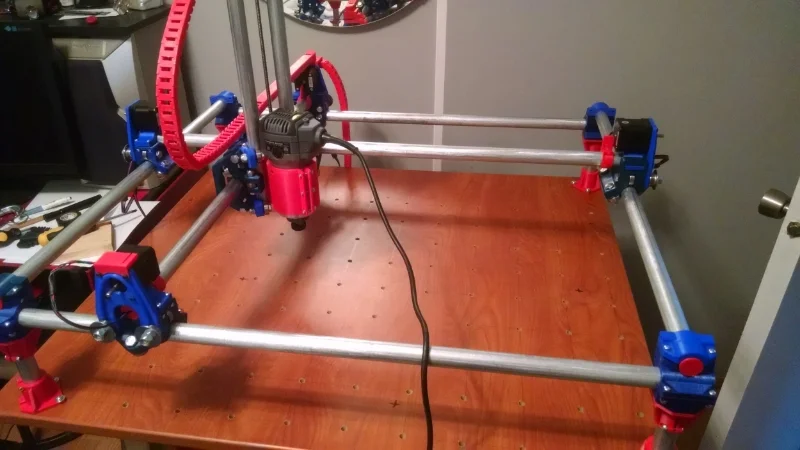

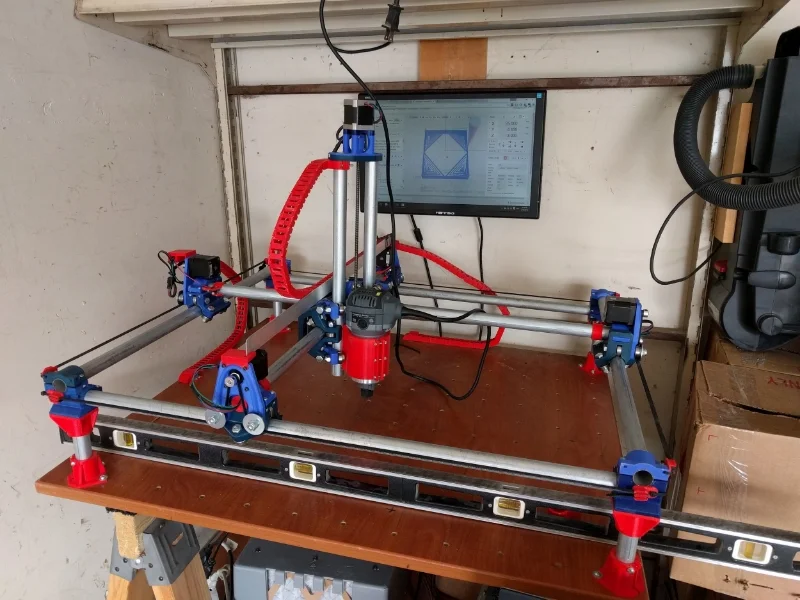

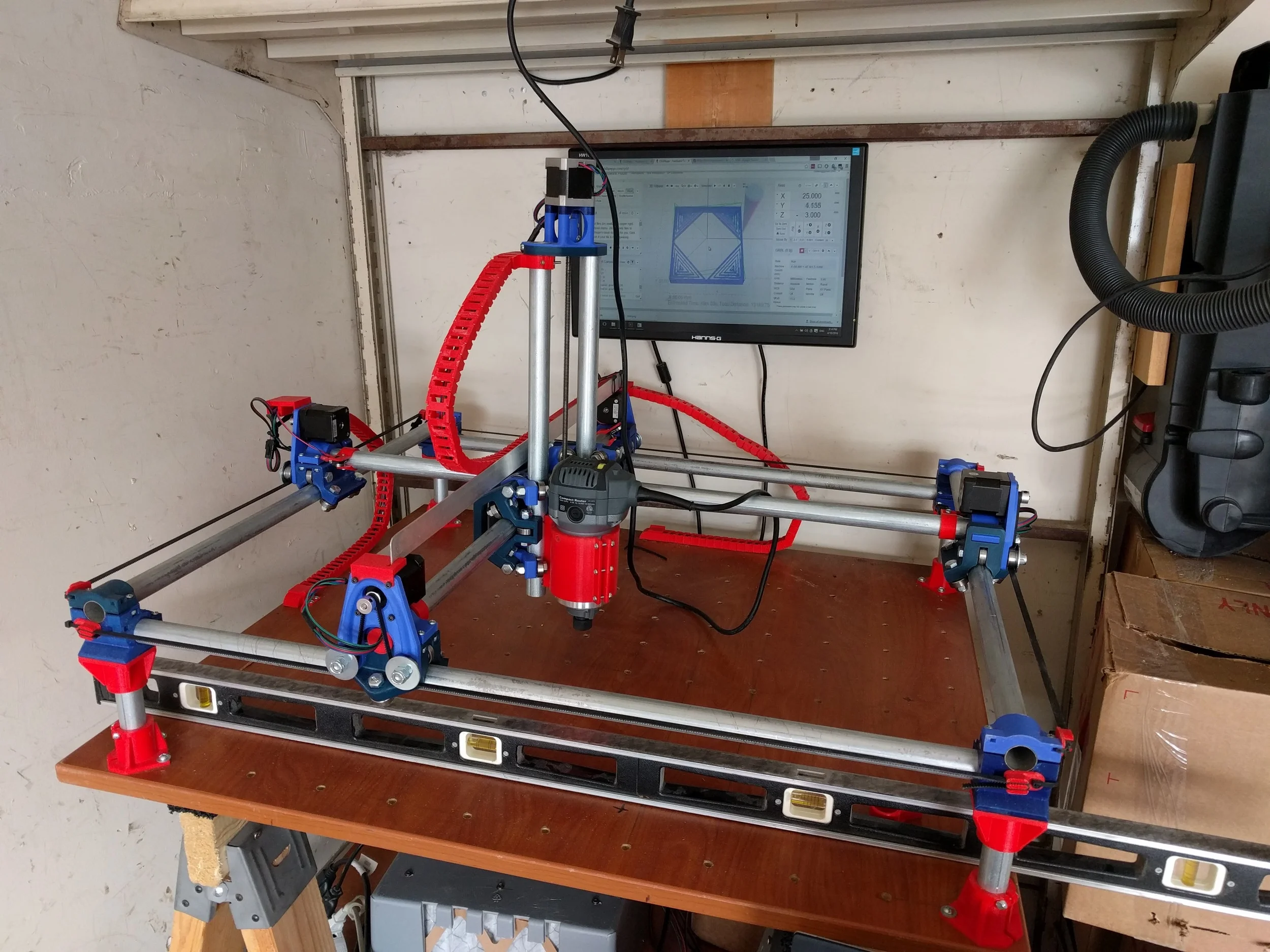

DIY CNC

8

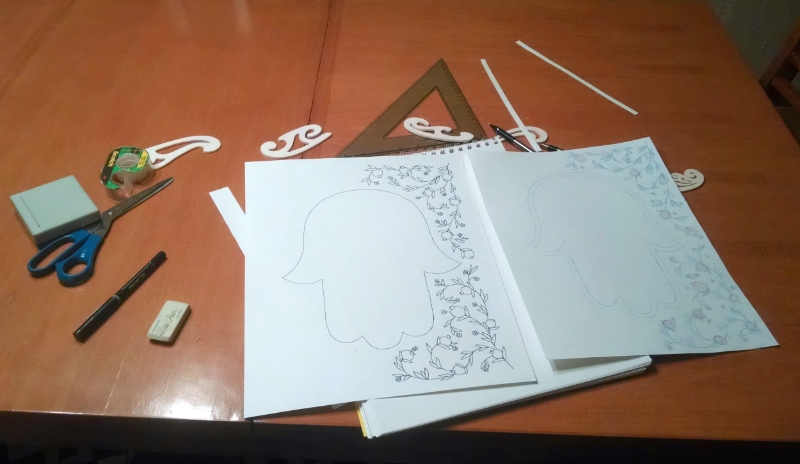

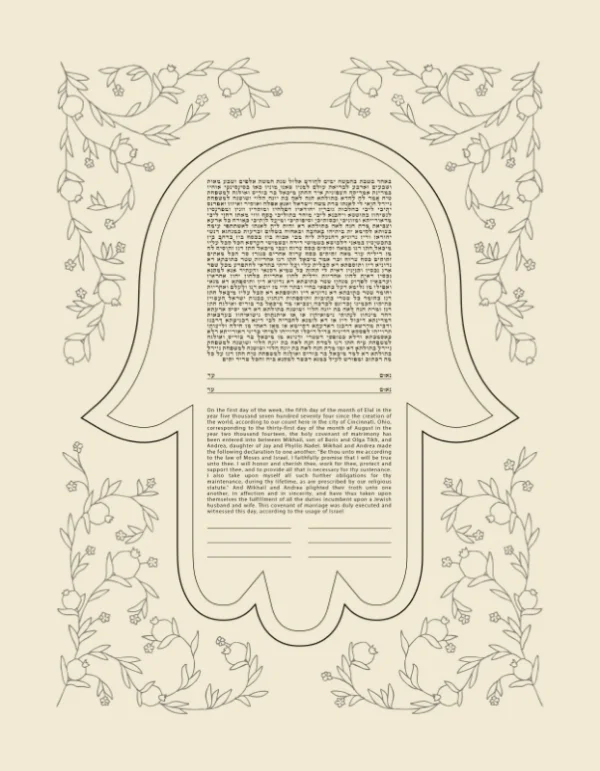

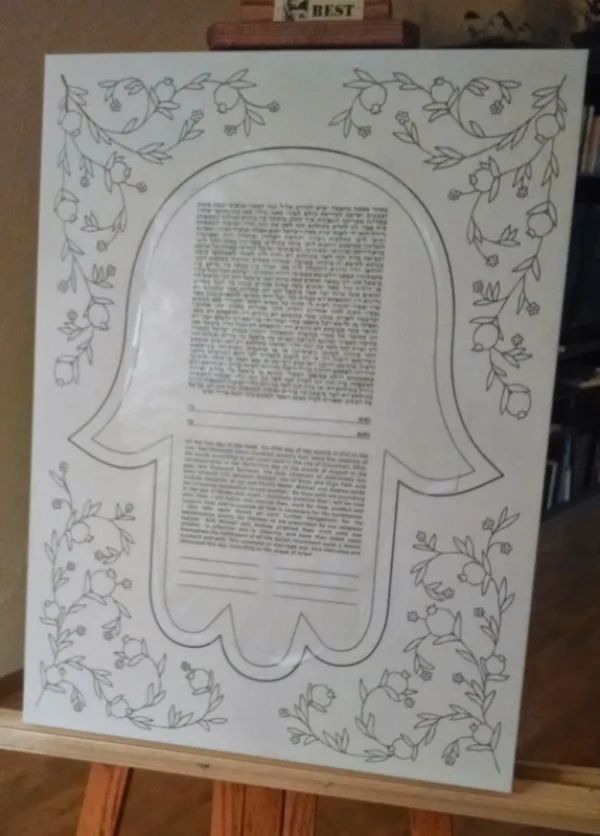

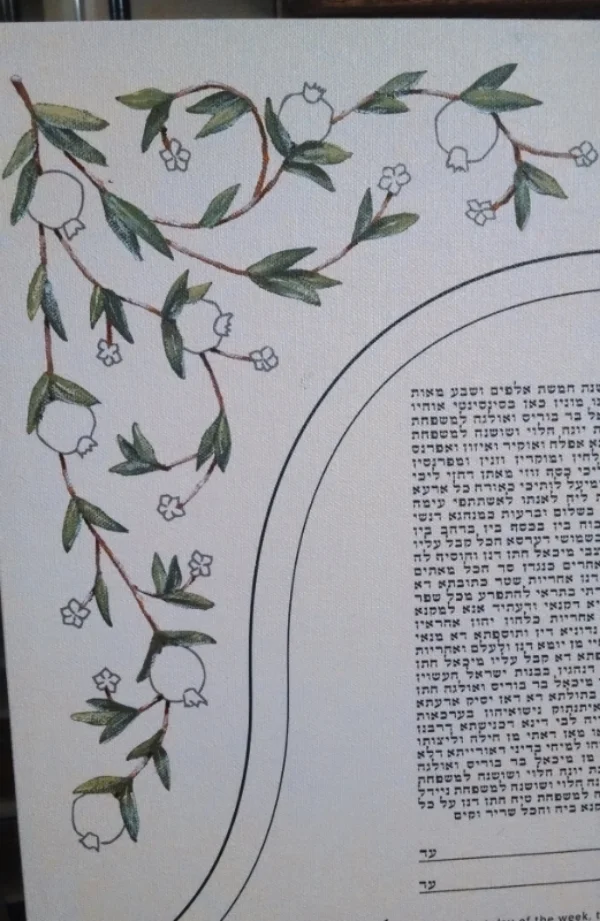

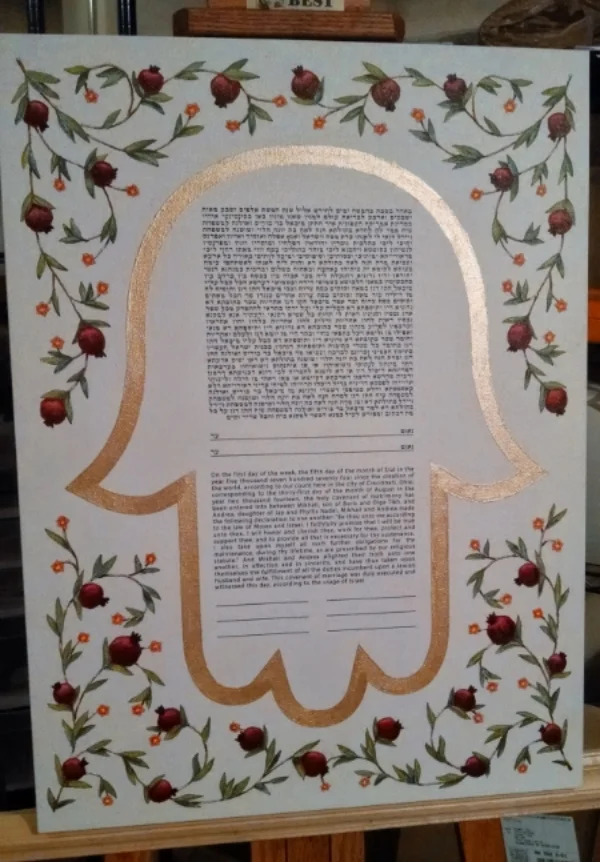

Painted Ketubah

6

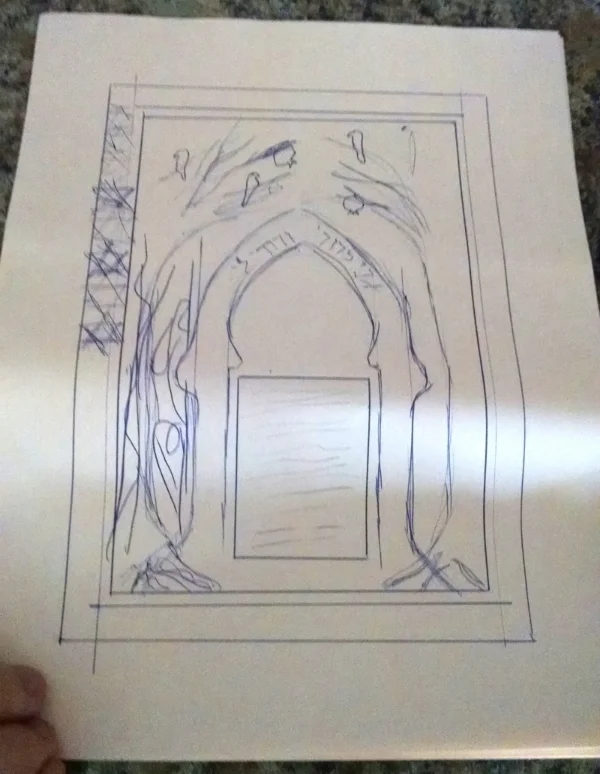

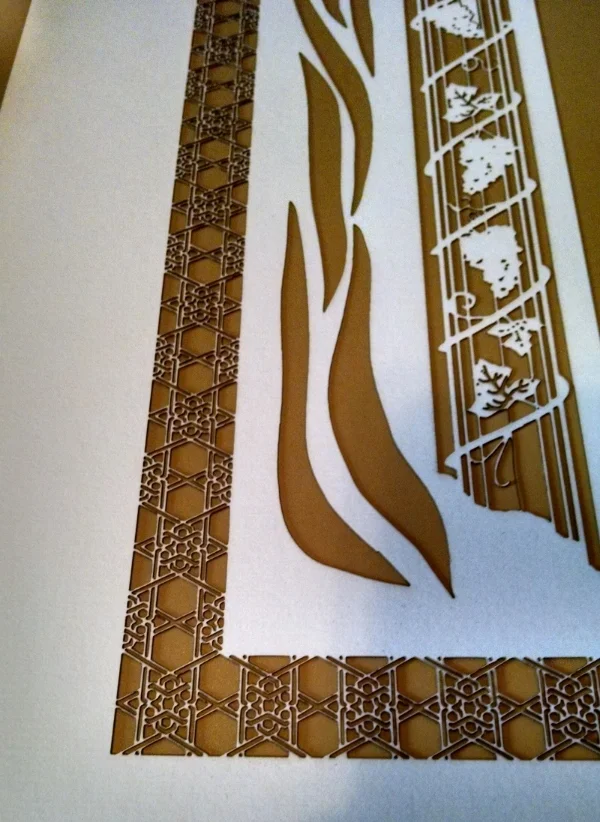

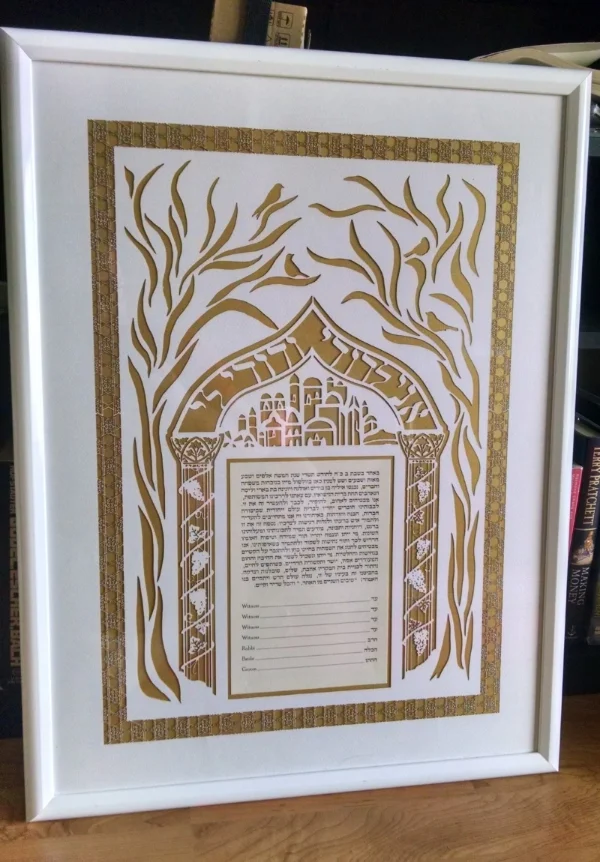

Laser Cut Ketubah

7

Halloween 2014

3

Movie Making

9

Halloween 2015

9

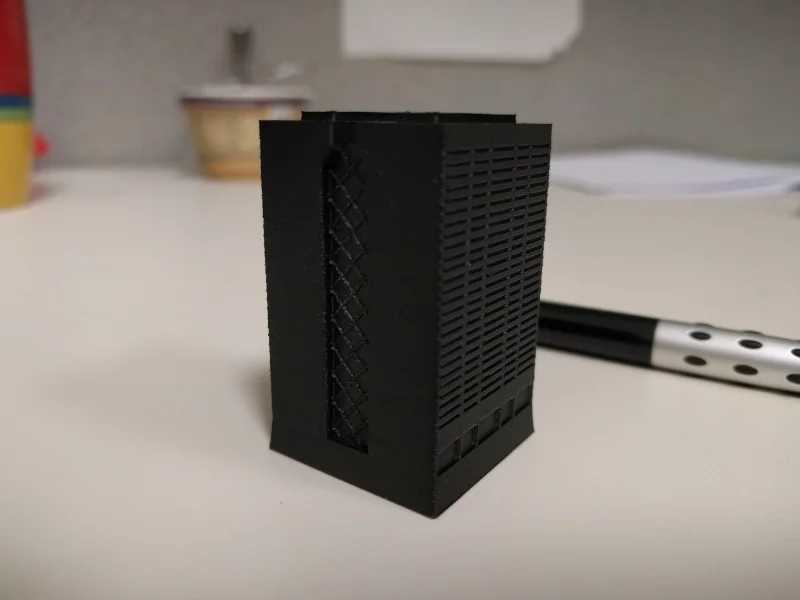

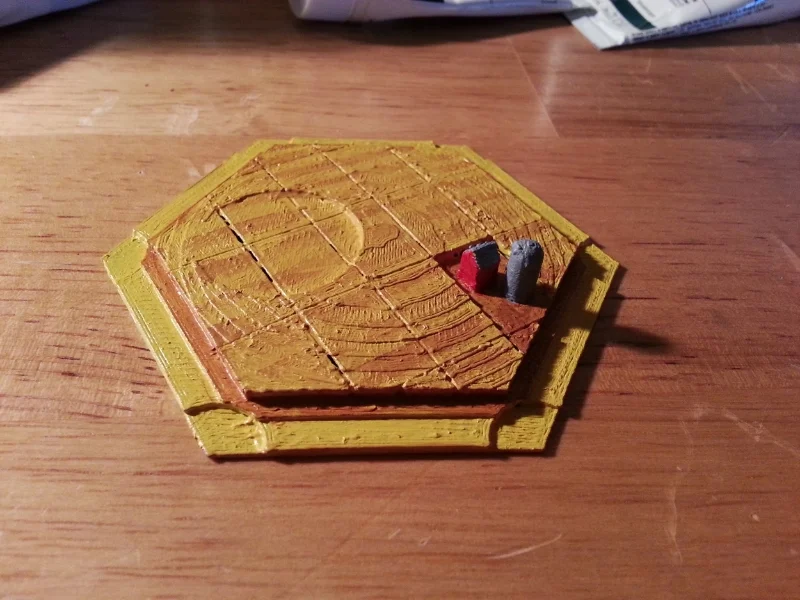

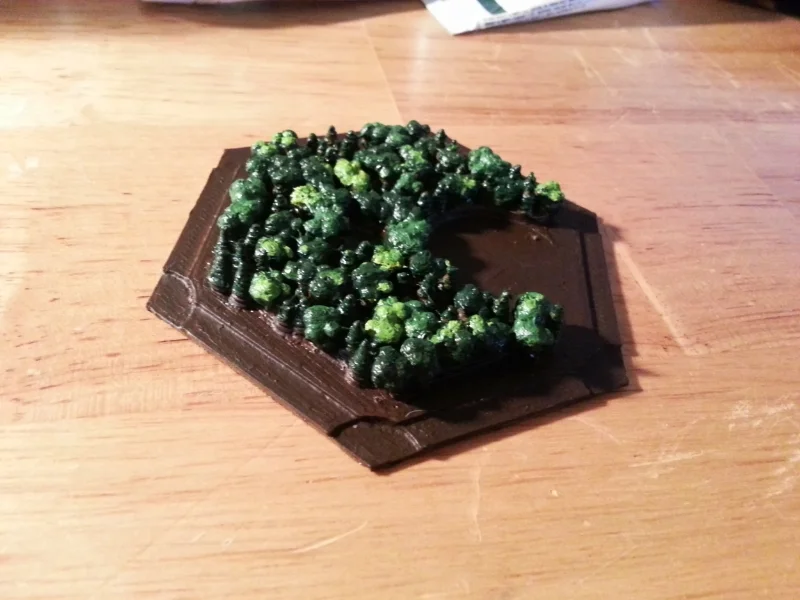

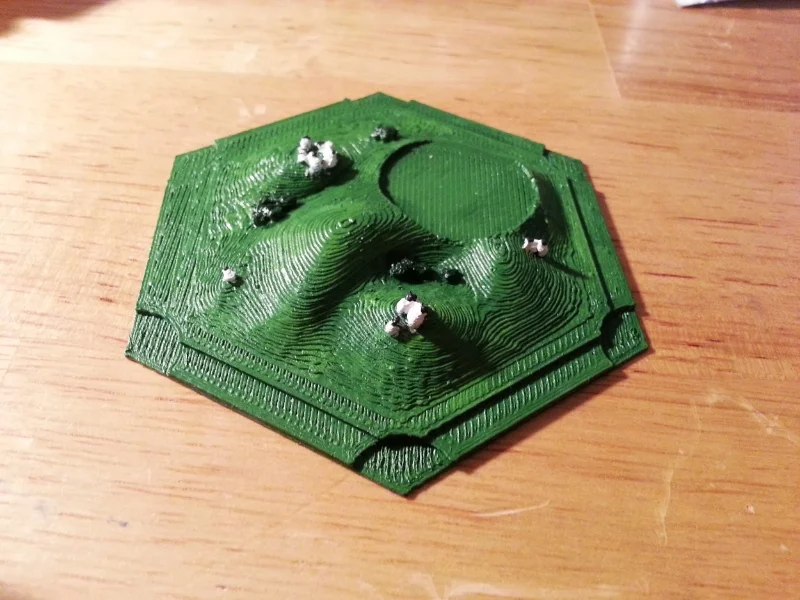

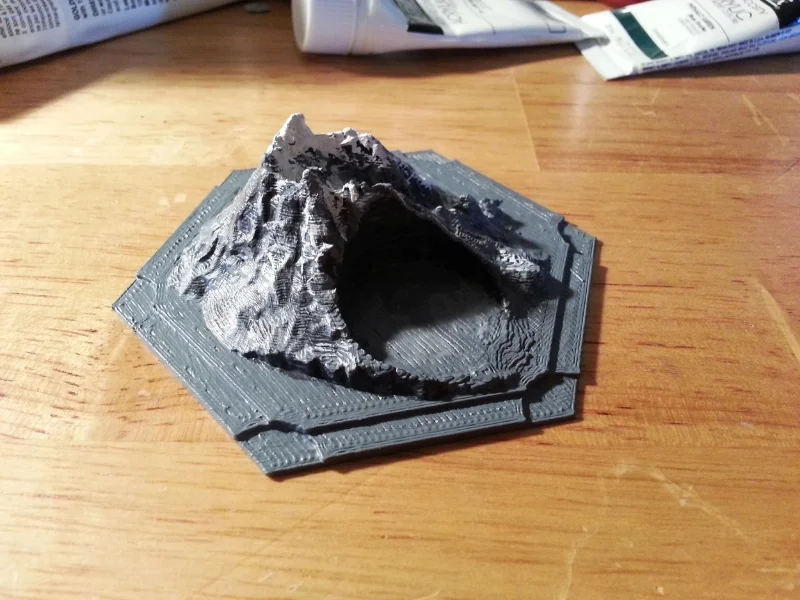

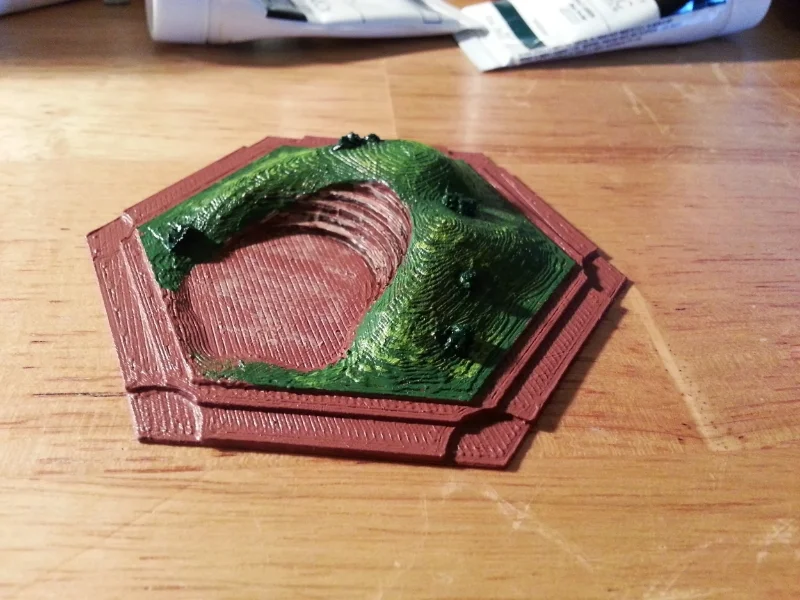

3D Settlers of Catan

6

Miscellaneous

5

Log to Foot Roller

0

DIY Mouthguard